forSte 39TJJ

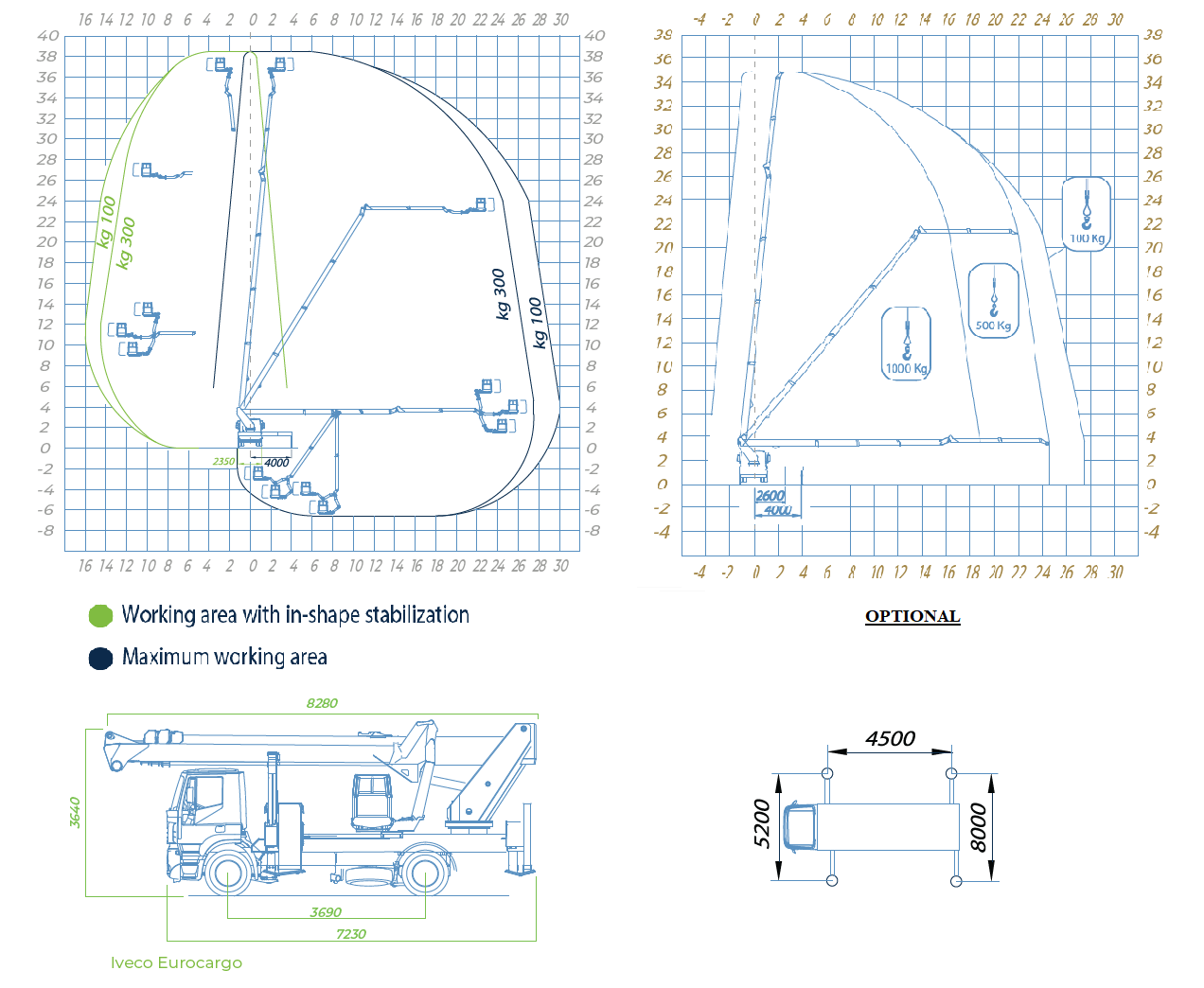

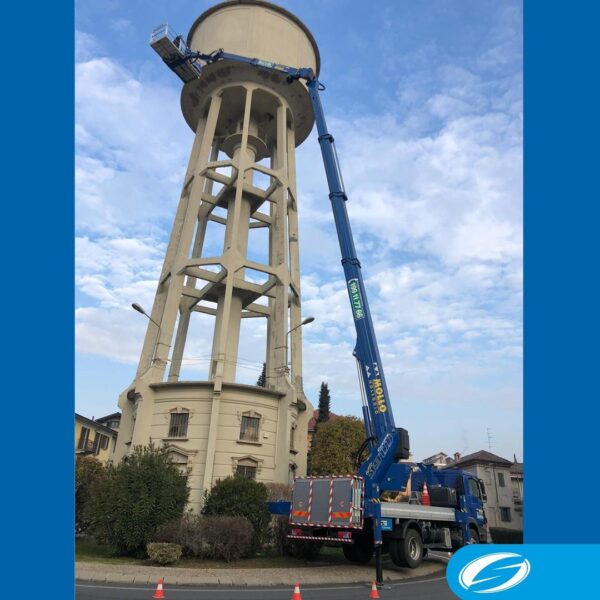

SOCAGE forSte 39TJJ is a double JIB telescopic aerial platform that can be installed on trucks from p.t.t 18 tons. This model is provided with a secondary boom that allows the equipment to perform maneuvers that would not be possible on a platform with only one JIB. It reaches a working height of 39m and a horizontal reach of 30m, in addition, has a large load capacity of 300 kg (3 operators + material).

Equipped as standard with a multi-zone stabilization system that allows the operator to choose between different options depending on the available space and the required features, the electronic platform control system automatically calculates the safe work area, based on the open position of the four stabilizers.

Can be equipped with a boom-mounted hydraulic winch with a capacity of 500/1000 kg, which can be used by removing the aluminum basket.

The extremely compact measurements of the set make it an excellent solution for working in hard-to-reach industrial and urban areas.

Compare