On construction sites, industrial work zones, and municipal jobs, cleanliness is a must, but it’s usually not enough to just brush debris aside. When it’s necessary to collect and dump dust, dirt, and debris, the easy-to-use sweeper/broom attachments gets the job done.

SWEEP, COLLECT AND DUMP DIRT AND OTHER DEBRIS WITH THE SWEEPER/BROOM ATTACHMENT

SKID STEER BROOM & SWEEPER

Landscapers, environmental companies, municipalities, general contractors, professional parking lot cleaners, and airports, all rely on this type of skid steer attachment to maintain the environment and comply with any environmental issues that they might face. To maximize their investment in this increasingly-popular type of equipment, making it a sweeper merits consideration.

We offer different sweeper attachments from Manitou (Gehl/Mustang) and Bobcat to choose from.

During operation, tough, poly bristles flick debris into the sweeper collection bucket – and when it’s full, you can lift, dump and dispose. It does the work of multiple clean-up attachments with optimal bristle-to-surface contact and highly productive efficiency. It’s ideal for site cleanup, daily dust abatement, road construction, airport maintenance, and more.

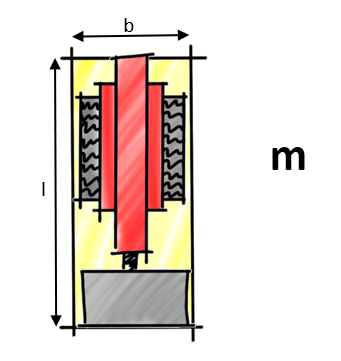

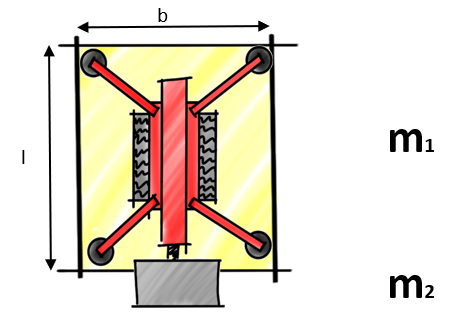

OPERATIONAL BASICS

The sweeper’s hydraulic motor spins durable bristles mounted to its rotating drum. Powerful flicking action sends dirt and debris flying into the attachment’s collection bucket. Bristles spin in either direction, forward or reverse.

When moving the loader in reverse, you can scrape mud and caked-on debris with the bucket wear edge as you sweep the material into the bucket – similar to sweeping with a hand broom and dustpan. When traveling forward, the bristles send material flying forward against a rubber flap. From there, materials go over the top of the bristles and into the bucket. When forward sweeping, keep the wear edge above the surface for optimum performance and wear edge life.

The five Bobcat sweeper models provide sweeping widths from 44’’ (1118 mm) to 84’’ (2134 mm), with bucket capacities from 0.15 to 0.33 m3 for the collection of debris.

FEATURES

- Poly bristles sweep and deposit debris in the sweeper bucket.

- Simply dump sweeper bucket when full. No need for multiple cleanup attachments.

- Cut through materials with the replaceable and reversible bucket cutting edge.

- Effectively operate in forward and reverse.

- Ideal for cleaning parking lots, pavements, docks, and warehouses, as well as industrial and recycling facilities, construction and demolition sites, and animal sheds in agriculture.

Broom attachments are selected by the material to be removed and the surface on which the broom is used. The EDGE pickup/hopper broom is a bi-directional collection broom that allows the operator to sweep forward and reverse, and gives excellent performance in milling, material pickup, road maintenance, and job-site cleanup at a cost-effective investment.

OPERATIONAL BASICS

The EDGE pickup/hopper broom is a single-motor broom and comes in widths ranging from 60” (1524 mm), 72’’ (1829 mm), and 84” (2134 mm).

FEATURES

- Ideal for milling, material pickup, parking lots, and road maintenance.

- Bi-directional broom operates forward or reverse.

- Bolt-on motor now featured with a protection guard.

- Quick-change broom sections allow for easy replacement.

- A rubber skirt and protecting shroud to keep dirt and debris contained.

- Front and side steps for easy access to and from the cab.

- Front bumper and no caster wheel allow you to get up close to objects without damaging the broom.

GUTTER BRUSH:

Cleans curbs, alongside buildings and other hard-to-reach areas. Widens the sweeper’s total width by one foot to allow more coverage per pass. Can be raised and stored vertically when not in use.

WATER KIT:

Keeps dust and debris under control when operating in tough environments, with jet nozzles spraying water evenly across a surface. This optional Dust Control Kit on hopper broom attachment includes 25 gals. tank, pump, and nozzles that mounted to top of hopper broom.

WHEEL KIT:

Available as an option for the 84-inch sweeper attachment, the wheel kit protects surfaces such as concrete, cobblestone, and asphalt from scrapes and scratches by suspending the cutting edge of the sweeper during forward travel. Two mounted caster wheels are included in the kit.

BRISTLES:

Ideal for all sweeping conditions, poly bristles provides better flicking action for effective debris removal. Steel bristle and combo bristle (poly and steel) sections are also available for stubborn debris. This option is only available on sweeper attachment.

WATERLESS DUST ABATEMENT:

It has its own filtering system for eliminating potentially large dust clouds, only available on broom attachment. Equipped with a 12V shaker dislodges loose debris from the filter directly into the hopper, unit is combined with hydraulic cylinder and two caster wheels and mounted on the side towards front of the broom. Suitable for example milling, material pickup, parking lot, road maintenance, and job-site cleanup applications, broom feature large industrial dust filter. This unit works well for indoor application cleanup, as it features a “waterless” dust abatement system.

In conclusion, by investing in quality pick-up brooms, you can effectively satisfy this job requirement while simultaneously optimizing the onsite use of skid steers.

The compact equipment specialists at Mayon Machinery have extensive knowledge of all makes of skid steer loaders and their corresponding attachments, and can therefore help you in choosing the right pick-up broom attachments for your respective type or types of work.