The Mayon Machinery (“MMRI”) team together with MOF (“MOF Company Subic, Inc.”) has recently completed another project at the site of the SMC cement batching plant by successfully transferring heavy kiln shells from the barge using 500T TEREX-DEMAG CC2500-1 crawler crane.

Project Overview

San Miguel Corporation (“SMC”) is one of the largest and most diversified conglomerates in the Philippines, originally founded in 1890. Its cement business has been conducted through its subsidiaries for over 50 years and has a total nominal annual production capacity of approximately 17.5 million MTPY of finished cement. To reduce dependence on imports and avoid delays in the delivery of critical infrastructure projects in the region, SMC has started construction of one of its cement batching plants in Calatagan, Batangas.

In preparation for the lifting of the heavy kiln shells, our team has been coordinating with the MOF from the planning stage through to the practical process.

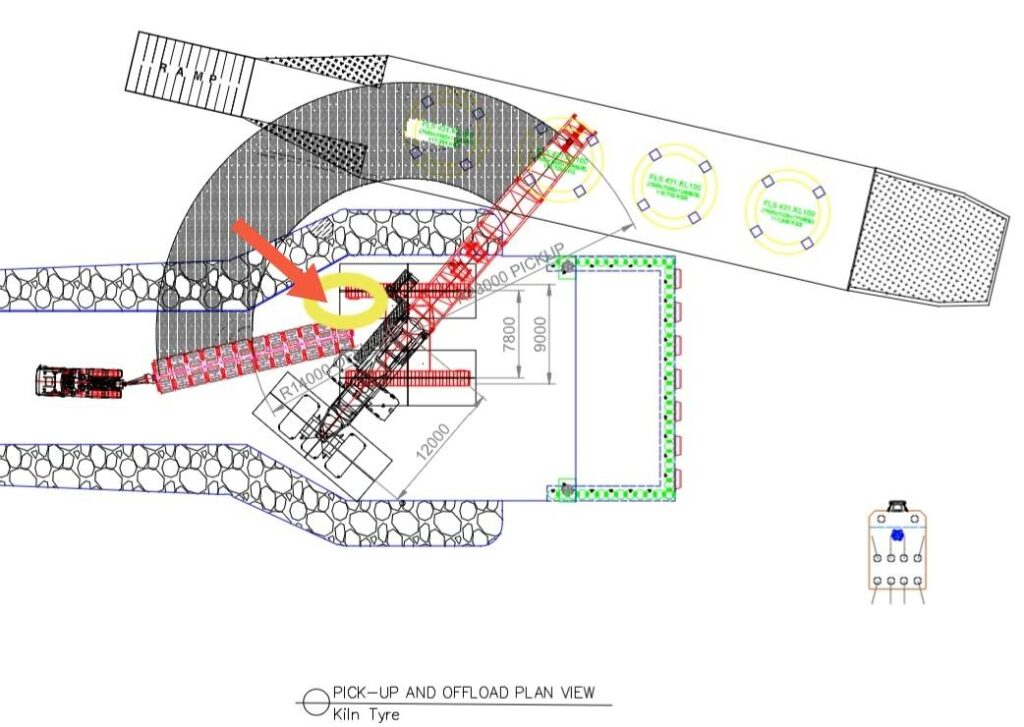

The MMC REBECAH barge cannot position itself as shown in the lifting plan, so MOF instructed the team with the new plan and positioned the barge alongside the jetty receiving platform.

Placing steel mats for the superlift tray in preparation for lifting the heavy kiln shells with a working radius of 24.5 meters, after which the barge will move forward to approach the next item to be lifted.

Locating the crane on the jetty required a high degree of precision. The positional constraints relating to the special steel mats combined with the lift capacity requirements, led the team to select a 500T TEREX-DEMAG CC2500-1 crawler crane to perform heavy lifting duties.

The Terex-Demag CC 2500-1 Crawler Crane has a 500T lifting capacity with a maximum boom length of 84 m and a derrick length of up to 139 m. This crane has an exceptional boom system optimized for high lifting and superlift operation. Its counterweight, superstructure, and superlift tray all add up to a total weight of 375 tons.

Outcome

MMRI met all of the challenges the clients faced and at a fraction of the cost of larger alternatives. Our fleet of rental cranes, the largest in the Philippines and Asia region, is designed to be versatile and adaptable to different sectors, in particular the loading of heavy items from barge to jetty without the aid of a barge crane. Contact us today for your heavy-lifting crane service including transport, lift, and installation with our most experienced operators, thus ensuring the utmost safety and efficiency throughout the project.