The Philippine General Hospital established in 1907 (also known as University of the Philippines–Philippine General Hospital or UP–Philippine General Hospital), simply referred to as UP–PGH or PGH, is a tertiary state-owned hospital administered and operated by the University of the Philippines Manila.

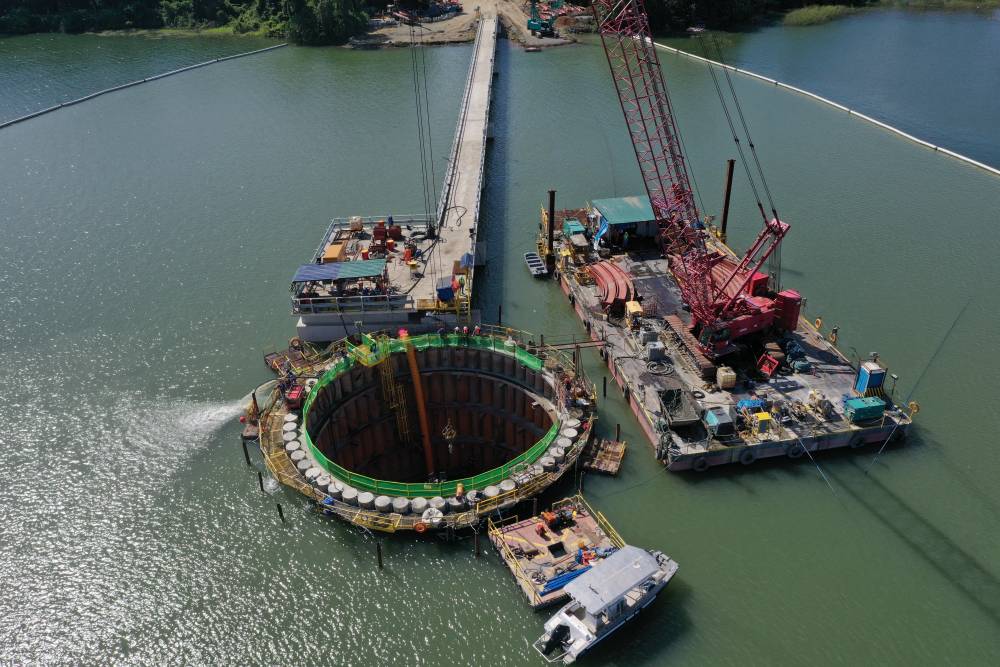

To enhance the capacity of PGH Manila in addressing the medical needs of the poor and the overcrowding concerns, the project PGH Multi-Specialty Building CP-01 is designed to house the neuroscience department as well as other specialties such as orthopedic, dermatology, oncology, laboratory, psychiatry, ICU, and ophthalmology, among others—to bring quality medical services to the Filipino people.

Mayon Machinery has been on this infrastructure project in 1st stage of sheet piling works with our Giken Silent Piler F111. This achievement is something to be proud of supplying the best equipment & service for speeding up the construction of this multispecialty building and for the betterment of Filipino people in need of medical interventions at the earliest time as well as alleviating noise and vibration concerns during operation for existing hospital performance.

Giken F111 Features & Benefits:

✅ Only 1100mm width can be adapted to more confined site conditions.

✅ 24m maximum of applicable pile length.

✅ A new control system manages the position of the press-in machine and controls load generation from press-in work during the operation, maximizing the durability of each part.

✅ Increased machine rigidity and guiding precision.

✅ The real-time information on piling operations can be displayed on a tablet PC which can be attached to the side of the Silent Piler.

✅ Able to install sheet piles into difficult ground conditions such as gravelly soil and cobble or boulder mixed soil even under restricted site conditions such as slopes or water whether conventional piling techniques would be ineffective with a Crush System for a hard ground press.

Every geological area has different Borehole data so it’s important to hire a Giken Silent Piler from a trustable supplier that has the experience you can depend on to understand the earth’s surface. Mayon Machinery as Giken Official Dealer has the piling works experience you can depend on to finish the job at hand. Whether you are on Luzon, the Visayas, or Mindanao Islands, Mayon Machinery can help.