MEWPs Effect On The Philippines Rental Market

Before MEWPs (AWPs), scaffolding was the main form of a solution on a worksite in the construction, petrochemical, and industrial sectors when working at height. Today, the rise of new and cutting-edge technology is advancing construction equipment to more modern and safe, enabling better quality work, along with timely completion of projects.

MEWPs have a number of advantages over scaffolding systems:

- A self-propelled MEWP can be driven to the worksite to begin work. Scaffolding must be manually transported to the worksite after curbside delivery and may require coordination with a third party that specializes in the erecting/dismantling of scaffolding systems.

- MEWPs allow for most jobs to be completed in the same or less time, with fewer workers than scaffolding requires. The less time the workers have to spend assembling, climbing up while carrying tools/supplies, and navigating around scaffolding, the more time, energy, and productivity are focused on getting the actual project done.

- MEWPs are highly maneuverable and can reach restricted areas efficiently where scaffolding simply can’t get to.

- MEWPs provide guardrail systems that are meant to support fall protection measures and differ from scaffolding in that it provides the safety that moves with the operator/occupants.

- A major benefit of self-propelled lifts is their ability to work every terrain and job site but not scaffolding.

Therefore, MEWPs are the cheaper, safer, and more efficient alternative to consider making the switch to such traditional methods.

“What happens if the machine stops working? Will they fail to deliver the machine at the expense of my construction project? What about after-sales services?”. Those questions are the customer’s concerns nowadays. With long experience in Japan, MAYON assures to offer our customers in the Philippines 24/7 support throughout the entire rental/sales process.

MAYON MACHINERY RENTRADE, INC – SALES & RENTAL

Head Office: 3rd Floor P & J Building, Lot 32, Blk. 69 M. Roxas Street, Corner Bayani Road AFPOVAI Phase 4, Fort Bonifacio, Taguig City

☎️ +63 (2) 776 0254 | 📩 info@mayonmachinery.com

We’ve all thought it before…“It won’t happen to me”

We’ve all been there, thinking, “It won’t happen to me.” But this false sense of invincibility can be the very reason why we overlook crucial safety measures. Every time we disregard even minor safety precautions, we are knowingly putting ourselves in harm’s way, exposing ourselves to unnecessary risks.

It’s time to change our mindset and prioritize safety. Instead of blindly dismissing safety initiatives, let’s take proactive steps to protect ourselves and prevent unfortunate accidents. By ensuring that we receive proper training, we equip ourselves with the knowledge and confidence to say, “It won’t happen to me” for the right reasons.

Here are some specific examples of safety precautions that people commonly overlook, along with their importance:

- Personal Protective Equipment (PPE): Neglecting to wear appropriate protective gear, such as helmets, gloves, or safety glasses, can leave us vulnerable to severe injuries. These seemingly minor items act as our first line of defense, shielding us from potential hazards and reducing the severity of accidents.

- Safe Equipment Operation: Failing to follow operational guidelines for machinery like AWP (aerial work platforms), telehandlers, forklifts, and others can lead to disastrous consequences. Proper training from TESDA accredited schools or institutions and adherence to safety protocols ensure that we understand the equipment’s capabilities, limitations, and correct usage, reducing the likelihood of accidents.

- Hazard Identification: Ignoring the importance of hazard identification can have severe repercussions. Recognizing potential dangers in our surroundings allows us to take appropriate preventive measures and create a safer environment for ourselves and others.

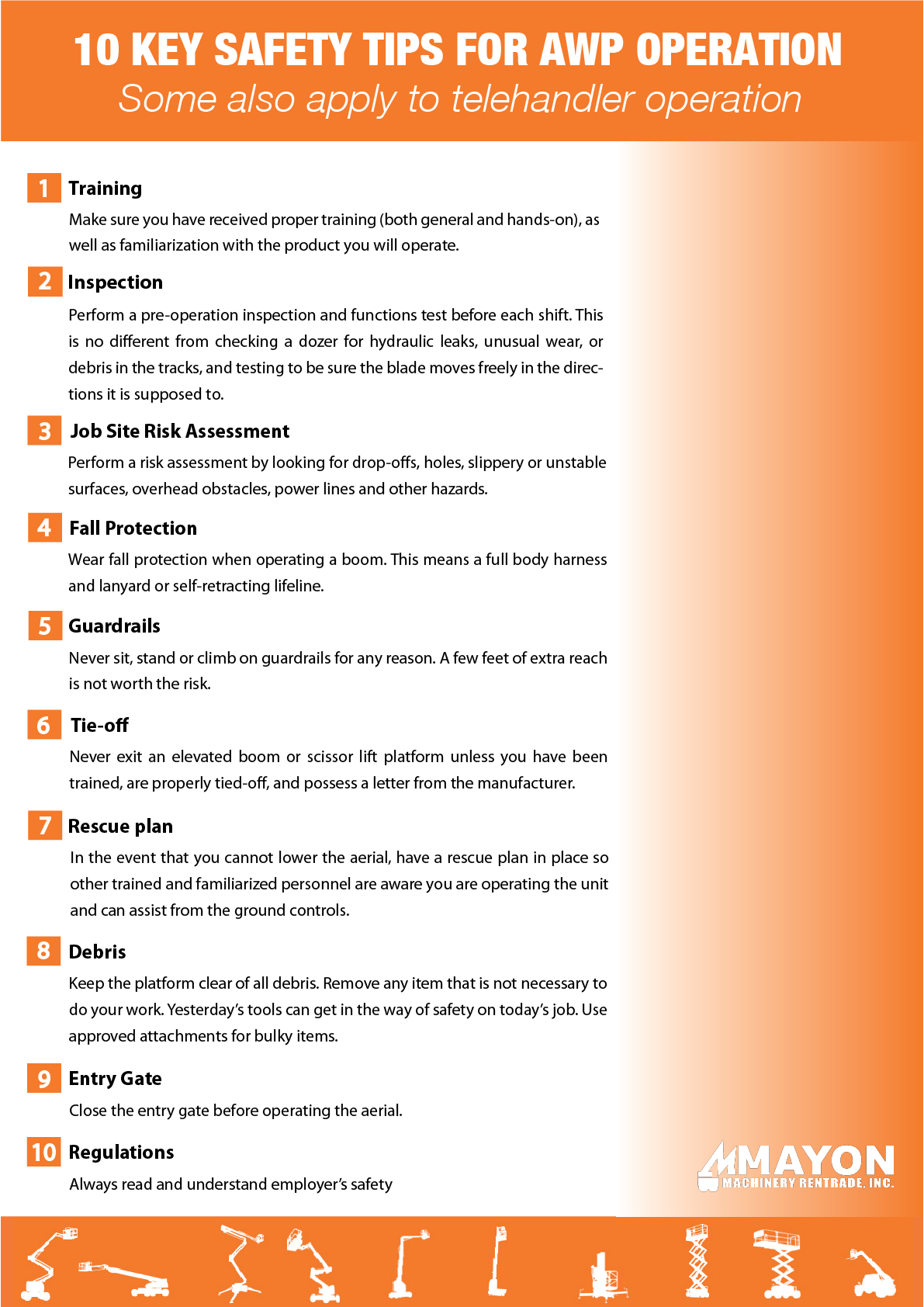

10 key safety tips for AWPs (MEWPs) Operation

It is crucial to grasp the real-life implications of not taking safety seriously. Consider the following examples that demonstrate the dire consequences of negligence:

- John, an experienced construction worker, decided not to wear his safety harness while working at heights. Tragically, he lost his balance and fell, suffering life-altering injuries. His decision to forgo a simple safety precaution forever changed his life.

- Sarah, a warehouse employee, underestimated the importance of following proper lifting techniques. Ignoring the guidelines, she attempted to lift a heavy object on her own, resulting in a debilitating back injury. Sarah’s momentary lapse of judgment led to long-term physical pain and reduced quality of life.

These stories remind us that no one is exempt from the risks associated with disregarding safety measures. Taking preventive action today can protect us from life-altering accidents tomorrow.

For further knowledge or to schedule training sessions, please don’t hesitate to contact us. At Mayon, we offer comprehensive advice and training on AWP, telehandlers, forklifts, and more. Reach out to us at info@mayonmachinery.com or call +63(2) 8776 0254.

Let’s prioritize our safety and create a culture where “it won’t happen to me” is backed by informed decisions and responsible actions. Together, we can safeguard ourselves and build a safer future.