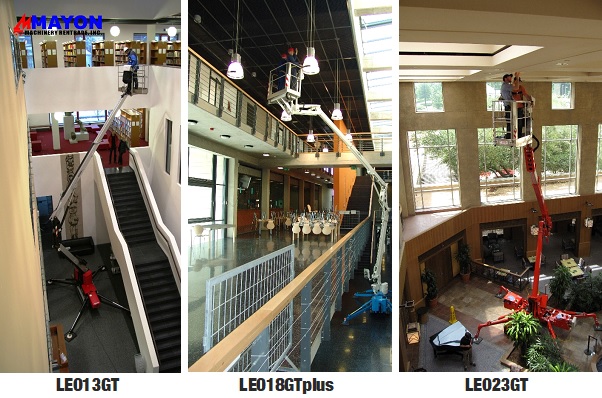

Building owners and facility managers place a high value on well-lit public spaces. In particular, large buildings in the education, healthcare, public and retail sectors are laid out to accommodate steady and large streams of visitors with the goal to create an airy and transparent environment that is friendly, accessible, and easy to navigate. They typically do not have a good solution for replacing interior light bulbs at height with 3-story (11m) or higher atriums when they burn out. The TEUPEN Spider Lifts LEO Series is a preferable solution for changing Fluorescent, Halogen, or LED lights without causing collateral damage or interruption of processes.

Benefits of using spider lifts to change light bulbs

- Compact size – fit through single & standard double doors

- Light – Low ground pressure protects sensitive surfaces

- Self-leveling, multi-position outrigger system permits to automatic set up of the machine in confined areas and on slopes

- Hydraulically height- & width adjustable track system permits narrowing and lowering the machine for passing entrances or widening the track footprint for more ground clearance and traction for driving alongside slopes or in terrain

- Dual power source available: A powerful and robust Petrol or Diesel Engine for outdoor use, electric motor or battery for silent and zero-emission work inside of buildings

- “Fuzzy-logic control box/ system” provides the smoothest boom operation without jerky movements in the industry. The key element of the new station will be shown a new information system, complete with graphics that are easy to read even in direct sunlight

The clearly-arranged control allows safe and easy operation. To drive on tracks or to set up using the stabilizer function, the cable/radio remote control comes in handy as the operator can move around the machine to get a better overview. Furthermore, on the control panel, an interactive display shows all available boom functions, safety information and allows error analysis.

Which model is suitable for your job?

To decide which model works best for your job, you should determine the factual problems of your facility. Here’s a look at the most important terms to identify the need:

- Who will use the equipment?

- How many people will be on the platform at once?

- Will they need operator or familiarization training?

- What kind of work will be performed?

- What are you lifting, and how much does it weigh?

- What are the obstacles on the worksite?

- Are there unusual work conditions or multiple shifts?

- What is your power source preference?

- Where will the equipment be used?

- Are you working on a single site or multiple sites?

- Is the work indoors, outdoors, or a combination?

- What site characteristics influence the lift’s use?

- Do you need to drive up or down a ramp?

- Do you need doorway access? Single, double, or larger?

- Is the ground level?

- Is there a slab, concrete, or asphalt floor?

- Will you have narrow or congested access?

- Is it a caustic or hazardous environment?

- Will fuel be readily available?

- Is there access to electricity on-site?

- How will the equipment be used?

- How high do you need to reach or work?

- How much outreach is needed?

- How much weight do you need to lift?

- How will you transport the equipment?

- When will the equipment be used?

- For how long?

In buildings with multiple usage and ever-changing events, there is always a time plan to be kept – therefore a flexible and versatile aerial lift solution is so important. Asking our expert at Mayon Machinery before making a hiring/purchasing decision will help ensure you find the best spider lift for replacing interior light bulbs.