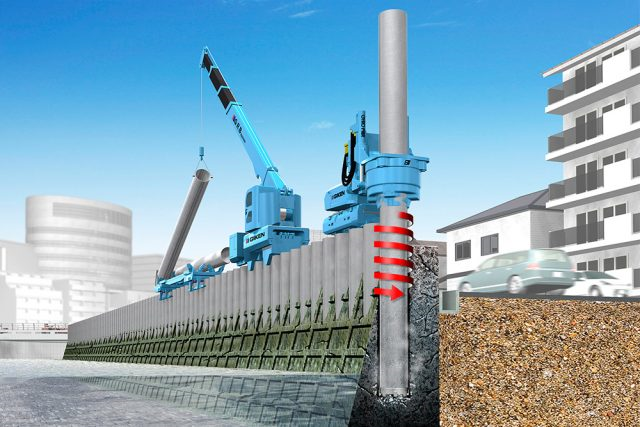

According to United Nations Industrial Development Organization (UNIDO), Tokyo reported about Silent Piler and its Piling Method. Giken manufactures a piling machine called Silent Piler™ and offers various construction technologies with the Press-in Method, worldwide. The Silent Piler™ characteristics, including but are not limited to, low noise, no vibration, and compactness, allow working in constrained areas, such as overwater, restricted headroom, and construction sites along with existing buildings.

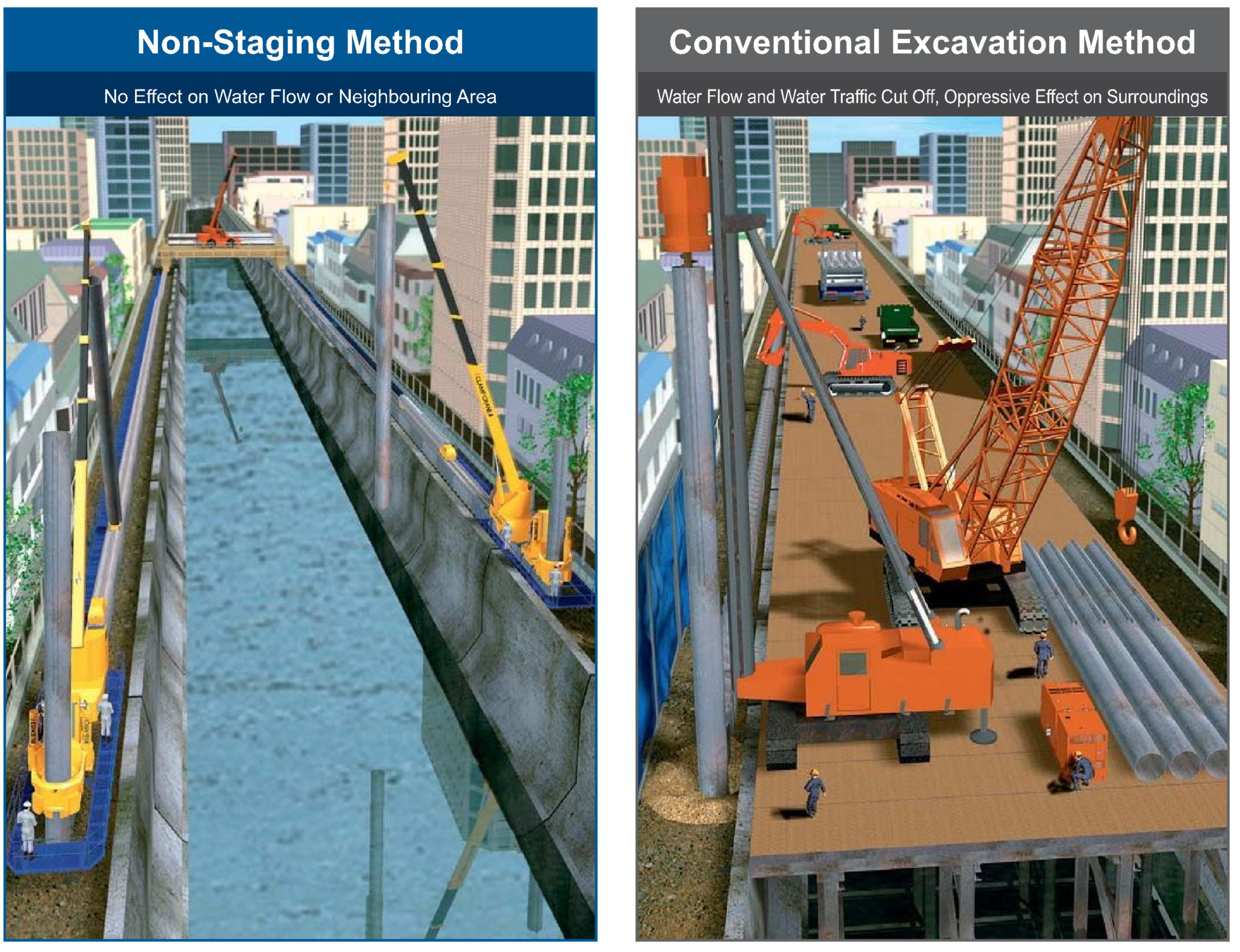

One of the representative Press-in Methods, the Non-Staging Method, provides benefit to the total construction work as it allows the installation of piles without a temporary stage, and hence reduces the construction cost and period.

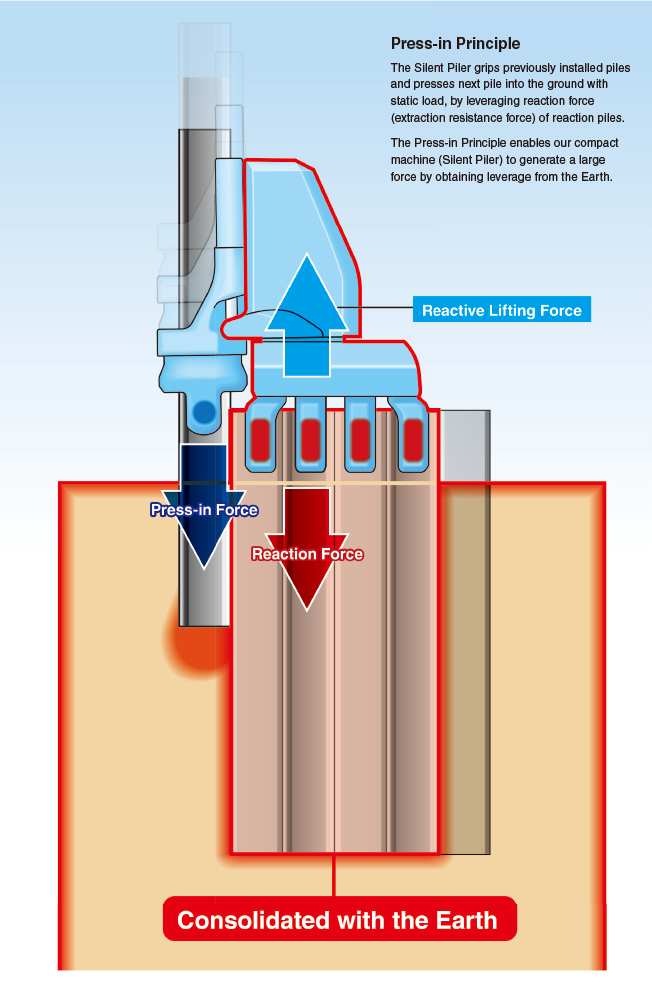

Press-in Principle

The Silent Piler grips the previously installed piles with the hydraulically operated Clamps. The next pile is then gripped by the Chuck at the press-in point and jacked into the ground with the static load generated by the hydraulic rams.

During the jacking, penetration resistance comprising of skin friction, toe resistance, and interlock resistance occur. It has the effect to convert a press-in force to a reactive lifting force but it is a greater force, provided by the extraction resistance of the reaction piles that resist this. Consequently, the down-stroke force acts on the pile to penetrate the ground.

Major Features and Advantages

- The press-in Method will not generate environmental pollution from construction such as noise and vibration.

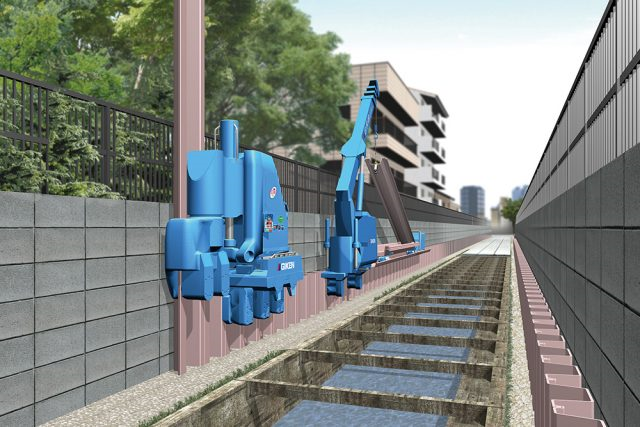

- Silent Piler is so light and compact that the extent of the piling activities can be minimized.

- Pre-fabricated piles produced at the plant are pressed-in directly, so high-quality completed piles can be built with peace of mind.

- Multiple sets of compact machines and apparatuses can be used at the same time to greatly shorten the construction period.

- Speedy piling progress is available because there are the least limits in working hours even at highly restricted areas and night works.

- All machines are so compact that it is not necessary to completely close active traffics.

- The performance of piles can be checked and controlled during the construction, allowing high-quality completed piles to be built

Applications:

【Disaster Risk Reduction and Restoration】

・Design and Construction of Resilient Implant Wall.

・Resilient River Revetment and Seawall.

・Disaster-prevention Levee against Earthquakes and Tsunamis.

・Disaster-prevention Berth by Pre-loaded Cantilevered Quay Wall.

・Seismic Isolation Technology against Liquefaction.

・Seismic Reinforcement on Road, Railways, and Bridge.

・Restraining Wall for Landslide Prevention.

We, Mayon Machinery are the Giken specialist in silent piling technology in the Philippines. Whenever you have piling projects, our knowledgeable team will help you to choose the optimal sheet piling method.

For more details, please contact:

MAYON MACHINERY RENTRADE, INC – SALES & RENTAL

Tel: +63 (2) 776 0254

Email: info@mayonmachinery.com/ sales@mayonmachinery.com