Why using aerial work platforms for tree-cutting service?

The correct tree trimming, pruning, and shaping tools and equipment are essential but often bulky when trying to work safely at height. To get people, tools, and equipment to the correct height there are times when traditional working solutions can limit productivity and endanger the arborist.

Aerial work platforms, also known as Mobile elevating work platforms (MEWPs), offer a flexible way to reach jobs at height – they are fully mobile and can access areas with restricted space, improve site safety, and save money.

A boom lift is a solid choice to manage tree work from a distance. It gets you exactly where you need to be in seconds, and gives you a safe and stable platform to perform your work. Besides being able to reach high spots, it can be moved around to accommodate position changes for tree pruning. This lift is essentially a platform with a long-jointed crane which is run by a hydraulic lift system, attached to a grounded base.

Crawler scissor lifts are an ideal way to get excellent access to the tree at different heights. Unlike a boom lift, the scissor lift isn’t too flexible. It moves up and down to provide easy and safe access to high trees. With bi-leveling technology, they have the ability to work on steep terrain or uneven surfaces (up to 20 ° longitudinally and 15 ° laterally) like forests.

Spider lifts are lightweight with low ground pressure, especially advantageous when working near garden pathways and manicured lawns.

The truck-mounted platforms are usually stouter and can generally extend to greater heights.

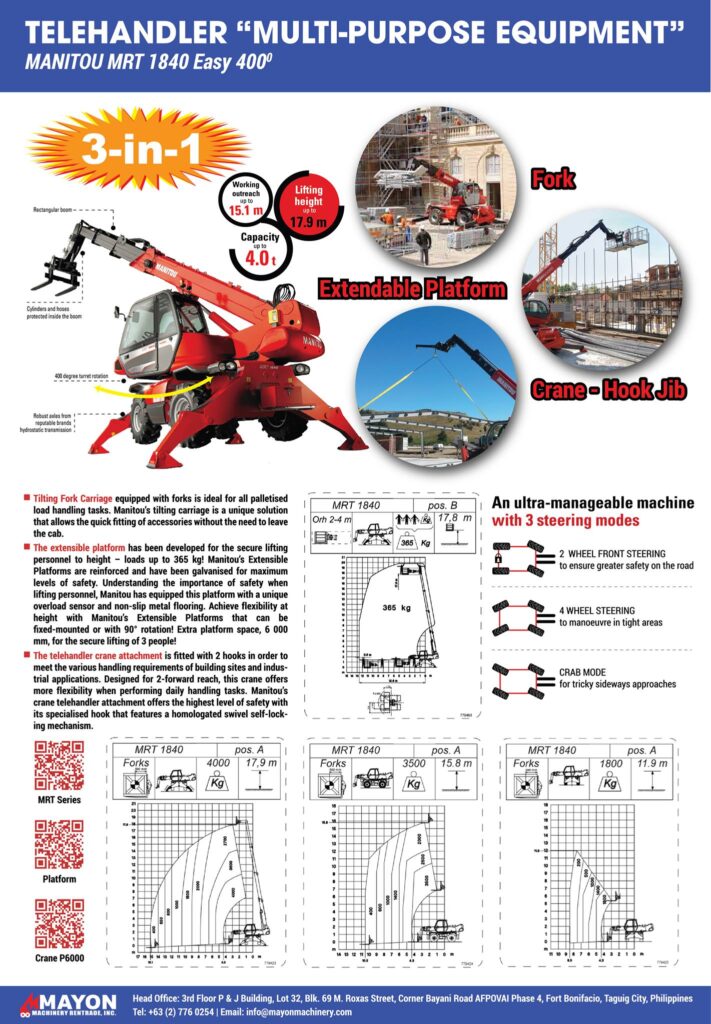

Rotating telehandlers equipped with a tree-cutting attachment (grapple saw) is boosting safety and efficiency for an arborist service working at significant heights cutting trees in a controlled way. This unique combination enables smaller sections of a tree to be removed and cleared away immediately, i.e., directly off the tree into a container or chipper without touching the ground and causing damage from falling wood.

“Whether you are a professional tree worker or a hobby gardener, if you are using a MEWP to work at height, make sure that you complete formal recognised operator training for the correct use of this specialist equipment”

To ensure safe operation and avoid incidents or machine damage, it is essential that all operators (employed and self-employed) undergo formal recognized operator training, which includes both theory and practical training and evaluation by a qualified person.

- Check the machine is not damaged, is safe to use, and functioning correctly.

- Take care when traveling to the work area – avoid the sloping ground.

- Make sure the ground can support the MEWP at all times.

- Always use suitable spreader plates under outriggers.

- Organize and manage segregated drop zones clear of MEWP base and structure.

- Take necessary precautions to protect the operator from the chainsaw.

- Do regular checks to make sure the MEWP is not sinking into the ground.

- Always wear an appropriate harness and ensure the lanyard is tied off to the designated anchor point inside the platform.

- Avoid making contact with or snagging branches – take care and use continual observation when raising and lowering the boom.

- Identify potential hazards such as overhead power lines and take necessary precautions to eliminate the risk of electrocution.

- Always be observant and operate the MEWP controls smoothly and with care.

- Never use the MEWP as a crane or secure supporting ropes to any part of the MEWP.

- Never take fuel up in the platform – always refuel the chainsaw on the ground.

- Never exceed rated capacities for total load, the maximum number of persons, or wind speed.

- Clear the MEWP of sawdust and debris.

- Check the machine for any damage – report any damage to the platform immediately.

- Leave the machine in a safe and secure place with all controls isolated – and keys removed.

- Report any damage to the owner – do not allow use of MEWP once damaged.

So, verify what piece of equipment best matches your needs before investing in a rental and purchasing.

Aerial work platforms provided by Mayon Machinery are the safest and most durable machines on the market. Your professional arborist can access the branches in a precise and calculated way with our products. Still not sure which is best for your tree care job? Get in contact at +63 (2) 776 0254 or send us an email at info@mayonmachinery.com or sales@mayonmachinery.com.