1. Comfortable operability

Smooth operation: Thorough review of inching operation for travel and loading/unloading

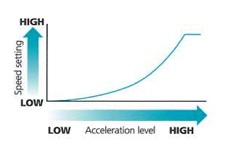

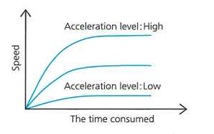

Driving Acceleration Characteristics

The acceleration characteristics are smoothly linked from low to high speeds, providing comfortable behavior at all speeds.

Driving acceleration characteristics

Improved the operability at low and medium speeds, making it gentler when making subtle inching operations, such as when fine-tuning your position, and quicker when you want to start off quickly.

Cargo handling inching performance

The low-speed range of the lift valve has been expanded, making it easier to perform delicate operations. In addition, the cargo handling motor has been changed from DC to AC, and the control at motor startup has been optimized to achieve both good response and ease of inching.

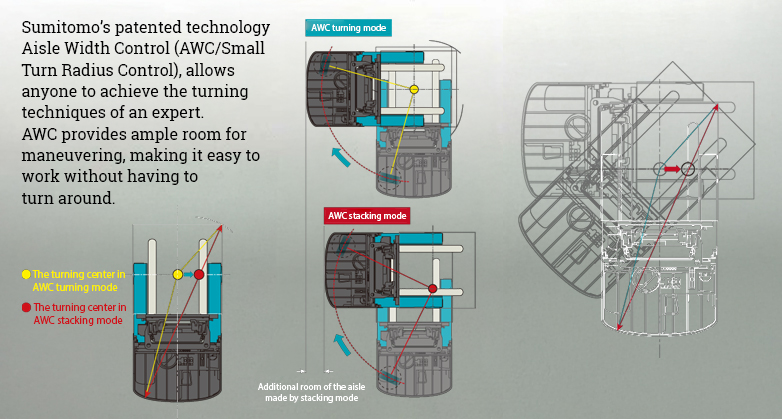

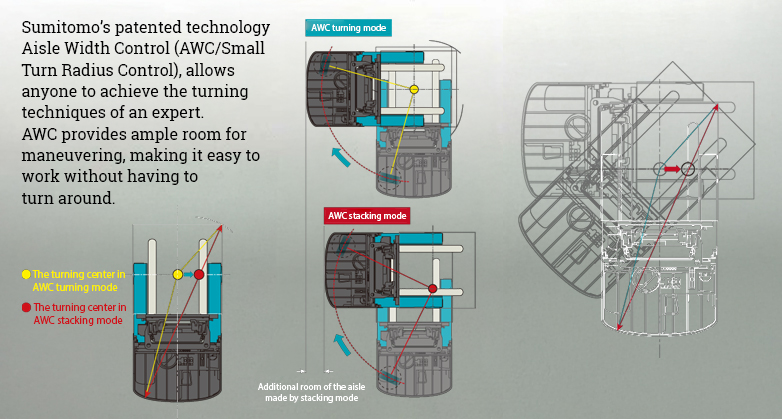

Smooth turning and excellent maneuverability in small spaces, thanks to Patented AWC (Small Turning Radius Control)

2. Economy

Achieving 7% energy savings

By completely overhauling the previous model, including converting the loader motor to AC, adding swing control, and improving the efficiency of the hydraulic equipment, a 7% energy saving has been achieved.

30 minutes of extra operating time

The reduced power consumption has extended the operating time by approximately 30 minutes compared to the previous model. It offers benefits in a variety of situations, such as reducing the need for auxiliary charging and making it easier to handle unexpected additional work.