Description

| Working height, max. | 23,20 m |

| Side reach, max. | 12,50 m (250 kg) / 15,60 m (80 kg) |

| Basket capacity, max. | 250 kg |

| Length with / without basket | 6,20 m / – |

| Transport height x width, min. | 1,99 m x 0,99 m |

| Total weight | 3050 kg |

| Tracks, adjustable | Hydraulical (Standard) |

| Stabilisation system | Automatic, multi-position |

| Power source – standard | 230 V electric motor + Diesel |

| Power source – optional | – |

|

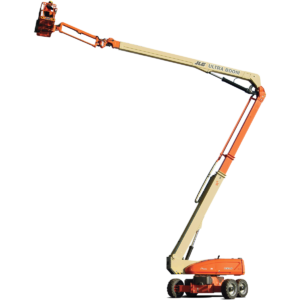

The LEO23TAs with the LEO21GT and LEO24GT, TEUPEN uses its new high-strength steel telescope technology in the team of the new LEO23T and sets again a new industry standard in this specific product segment: With 250 kg platform capacity the LEO23T has a 12,50 m outreach, at 80 kg it even reaches 15,60 m. |

|

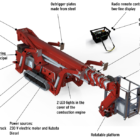

Engineered for operatorsA boom speed control depending on range, swivelling even over narrow outrigger setting, a fully-proportional, load–sensing hydraulic system, a large 25 l fuel tank and a new easy-to-use emergency control system powered by an independent electric drive to make a handpump obsolete – all are standard features. |

|

Innovative boom technologyWithin the new, high-strength steel boom telescopes all cables, hoses and hydraulic cylinders are safely routed through the booms and therefore protected against damage, dirt and all weather conditions – clean and above all safe quality. |

|

Radio remote control and interactive displayThe clearly-arranged control allows safe and easy operation. To drive on tracks or to set up using the stabiliser function, the radio remote control comes in handy as the operator can move around the machine to get a better overview. Furthermore, a display offers a complete overview of all important information. The radio remote control is included in the standard configuration. |

|

Coming home and memory functionThe operator can use the “coming home function”, i.e. the automatic return of the boom into its transport position along with the all new “memory function”. Any point in the working diagram can be saved and returned to at the push of a button. |

|

The TEUPEN track driveThe track drive with non-marking rubber tracks provides easy, precise maneuvering and protects sensitive flooring. In the standard configuration the LEO23T is equipped with a hydraulically height- and width adjustable track drive at a touch of a button: The narrow setting decreases the width of the machine, in wide it increases ground clearance and stability. Also levelled driving alongside slopes is possible. |

|

High-performance stabiliser systemSafe positioning even with little space: the multi-position stabiliser system permits to automatically set up the machine in confined areas and on slopes. It offers three different setup positions: Both sides wide, one side wide and one side narrow or both sides narrow. In terrain or over obstacles the stabilisers overcome a height difference of 1,20 m. |

|

Dual power sourceThe right power source for every job: in the standard version the LEO23T is equipped with a 230 V electric motor for a silent and zero-emission work inside of buildings. For outdoor use it has a powerful and robust Diesel engine. |

|

Innovative emergency control systemThe battery powered emergency lowering function makes the use of a hand pump obsolete. The direct hydraulic operating system is easily accessible and follows an easy and intuitive 1-2-3 guidance system. |