When it comes to choosing the best bucket for your compact loaders, there are several factors to consider. Here are some tips to help you make the right choice:

Table of Contents

1 – Consider the size:

The size of the bucket you choose will depend on the size of your compact loader and the type of work you will be doing. Larger buckets are ideal for heavy-duty tasks, while smaller buckets are better suited for lighter jobs.

FOR LIGHTER-DUTY JOBS:

GENERAL PURPOSE AND DIRT BUCKETS

For daily use with smaller compact loaders or occasional use on some of larger machines, you can’t beat the versatility of general-purpose and dirt buckets. The skid-bar design provides wear protection to the bucket bottom, backs up the cutting edge, and adds strength to the bottom of the bucket. A flat back on the bucket exterior provides a secure mount for quick-attachment systems such as Bob-Tach® system or All-Tach™. A round back inside the bucket enhances loading and cleaning out. A replaceable high-carbon steel cutting edge provides a long bucket life.

GENERAL PURPOSE BUCKET

The standard bucket for compact machines and a good choice for low-hour users on some larger loaders. General-purpose buckets are ideal for light-duty grading and leveling applications as well as material handling.

- Similar to dirt bucket with a longer bottom

- Perfect for light-duty grading, leveling, and material handling

- Excellent cutting-edge visibility

- Good bucket breakout force

The standard bucket on smaller compact loaders. Designed specifically for digging and moving dirt, gravel, and other loose materials. They typically have a flat bottom and straight sides that provide maximum cutting and digging power.

- Similar to general purpose bucket, but with a shorter bottom and low back

- Fair cutting-edge visibility

- Excellent bucket breakout force

FOR HEAVY-DUTY JOBS:

CONSTRUCTION/ INDUSTRIAL AND LOW-PROFILE BUCKETS

With more durability for your toughest jobs, nothing provides longer wear in extreme applications. It’s designed for handling heavy materials and performing digging and earthmoving tasks. Gehl C/I buckets generally have a more curved profile, while Bobcat C/I buckets tend to have a more angled profile. The design can affect the bucket’s digging and earthmoving performance and may be preferred based on personal preference or specific job requirements.

The standard for performance and strength.

- Highest breakout forces

- Good cutting-edge visibility

- Shorter bottom and less capacity

These the most popular low-profile buckets are ideal for grading, leveling, carrying, loading, and other material handling.

- Good breakout force

- Excellent cutting-edge visibility

- Similar to the C/I bucket, but with slightly longer bottom for better visibility and increased capacity

Designed for larger skid loaders and compact track loaders. These buckets are built even stronger than C/I and low-profile buckets. While Heavy-Duty Construction/Industrial buckets typically feature thicker steel construction, reinforced bucket bottoms, and wear-resistant cutting edges for use in demanding construction and industrial applications. Severe-Duty Construction/Industrial buckets are even more rugged and durable than heavy-duty buckets and are designed for use in extreme conditions such as demolition, quarrying, and mining.

- More capacity than C/I or low-profile buckets

- Double-walled top crossmember

- Stronger mounting frame

- Higher back and longer bottom

- Thicker and taller side cutting edges

SPECIALTY BUCKETS:

FERTILIZER AND GRAIN BUCKETS

When choosing a fertilizer or grain bucket for a compact loader, it’s important to consider the specific agricultural materials being handled and any specific requirements for the job. For example, if handling corrosive fertilizers, a bucket with a corrosion-resistant coating may be necessary to prevent damage and prolong the bucket’s lifespan. Similarly, if handling delicate grain or feed, a bucket with a smooth interior and larger capacity may be preferable.

- Move large volumes of granular material

- Minimum spillage over the front edge thanks to an increased rollback feature

Gehl Snow and Light Material buckets can hold slightly more material than the Bobcat buckets due to having a slightly more curved design, which may make them more efficient for scooping and dumping materials. While the Gehl buckets may have a slight advantage in terms of capacity and durability, the Bobcat buckets may offer more versatility with their universal mounting system.

- Ideal for handling large, low-density materials

- Large-capacity buckets with a high-back design

- Sizes range from 1562 to 2578 mm wide

Rock buckets are heavy-duty attachments ideal for picking up stones and large awkward debris. This kind of bucket is a “must-have” for skid steer operators in the agricultural, commercial, and landscaping industries.

- Skeletal design collects rocks while leaving soil behind

- Models ranging from 1549 to 2223 mm wide

2 – Choose the right material:

Buckets are available in a variety of materials such as steel, aluminum, and composite. Steel buckets are more durable and ideal for heavy-duty work, while aluminum buckets are lightweight and easier to handle.

3 – Think about the shape:

The shape of the bucket can affect its performance. A wider bucket will have a larger capacity and will be better for moving loose materials such as gravel and sand. A narrower bucket will be better for digging and excavating.

4 – Consider the teeth or cutting edge:

Some buckets come with teeth that can help you dig into hard ground or break up tough material. If you will be doing a lot of digging or excavation work, a bucket with teeth may be a good choice.

5 – Look for versatility:

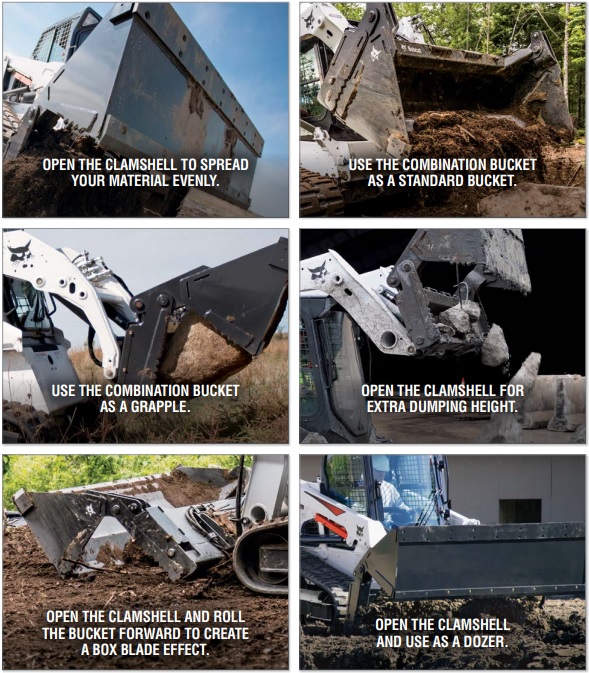

Some buckets are designed to be used for multiple purposes, such as grading, leveling, digging, and grappling. If you need a bucket that can handle a variety of tasks, look for one that is versatile, for example, 4-in-1 a combination bucket.

- Bolt-on corner cutting edges to protect the corners of your bucket; reversible.

- Reinforced bucket bottom and clamshell improve strength and rigidity.

- Interlocking serrated grapple edges to hold objects securely – even heavy or odd-shaped materials.

6 – Consider the price:

The cost of the bucket will depend on its size, material, and features. Choose a bucket that fits your budget but don’t compromise on quality.

By considering these factors, you can choose the best bucket for your compact loader that will meet your needs and help you get the job done efficiently. If you’re still unable to select the right bucket, please consult our team at Mayon Machinery to get the best one for your application.