Power is a fundamental necessity for utility companies and power producers. With the ever-growing energy demand, repairing damage to the distribution grid is a fact of life for most electric utility companies, while new manufacturing facilities are also being constructed. In the Philippines, a nation prone to natural disasters like typhoons, earthquakes, and lightning strikes, these challenges are particularly pronounced, often leaving consumers without power for days or even weeks. Typhoons can cause serious harm to power infrastructure by knocking down utility poles and damaging transmission wires, leading to prolonged power outages across entire regions. With the Philippines situated in a seismically active region, earthquakes can also disrupt the energy supply by causing structural damage to infrastructure. Lightning strikes are another constant threat to power distribution systems, often resulting in equipment failures and power outages. Therefore, ensuring the reliability of power infrastructure under these circumstances is of the utmost importance. From construction to maintenance, we’re ready with the broadest and most versatile fleet of rental equipment and lifting solutions available for the Philippines’ energy industry.

Table of Contents

Specific Examples of Integrated Lifting Solutions

- Typhoon Resilience: The Philippines is no stranger to devastating typhoons. Integrated lifting solutions have played a crucial role in the energy industry’s ability to swiftly respond to typhoon-related damage. For instance, after Typhoon Haiyan in 2013, which caused extensive power line damage, aerial lifts were used to access and repair electrical poles efficiently. This rapid response helped restore power to affected communities faster than traditional methods.

Photo courtesy of using our Haulotte HA260PX from one of the electrical substations at National Grid Corporation of the Philippines – Labrador in Pangasinan

AlmaCrawler Scissor Lift BIBI 1090 is used for power station maintenance

- Solar Panel Installations: With the growing interest in renewable energy, the Philippines’ energy industry is increasingly turning to solar power. Installing solar panels on rooftops or in remote areas requires specialized equipment like scissor lifts, telehandlers, or a special solar pile driver. These lifting solutions simplify the installation process and improve efficiency.

- Smart Grid Expansion: As the demand for energy management grows, the integration of smart grids is becoming essential. Aerial lifts have been instrumental in installing smart grid components like sensors and meters on utility poles, ensuring a more reliable power distribution system.

- Installing transmission wires and pylon erection: The wires and pylons themselves can be very heavy, so they often require special equipment to lift them into place. On such a project, a crane or a telehandler can make the job much easier. Heavy materials can easily be moved around the installation site and repairs are much quicker and more effective. Many of our customers use a rotating telehandler instead of a crane, partly because of their compact size and increased versatility with a hundred attachments compatible in just a single machine for multifunctional use in confined spaces where cranes cannot be used. Unlike cranes, rotating telehandlers feature 360° rotation, offering height and slew restriction and automatic attachment recognition. Additionally, they also include an onboard self-diagnostic computer and remote control operation.

A telehandler equipped with a man basket

Handle loads with an extension jib easily and safely

Installing extremely heavy transmission poles

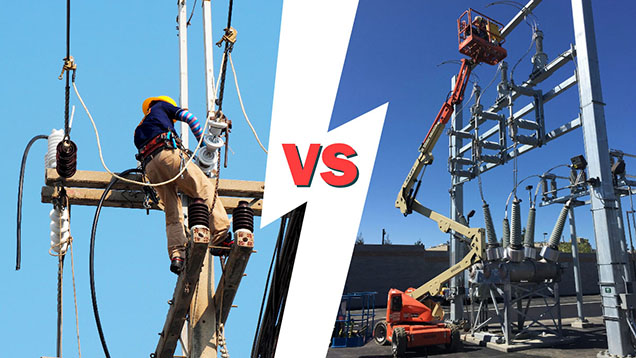

Enhancing Safety and Productivity with Aerial Lifts vs. Traditional Ways Such As Climbing or Scaffolding

Aerial lifts, including boom lifts, crawler lifts, and truck-mounted lifts, provide an enhanced level of safety and productivity compared to traditional ways such as climbing or scaffolding while ensuring workers have access to all the tools they need. These lifts offer a safe working platform, especially crucial for tasks involving power lines. By eliminating the need for constant ladder climbing, aerial lifts significantly mitigate fall risks. Consequently, aerial lifts prove invaluable for expediting substation maintenance operations.

Benefits of Aerial Lifts:

- Seamless Access Over Fences and Along Cable Lines

- Immediate Deployment with No Setup or Tear Down Required

- Exceptional Performance on Uneven Ground

| Scaffolding | Aerial Lifts (15 to 23m high) (For 400 kV substation – 750 kV substation) | |

| UNEVEN GROUND AT SITE | Safety risk Scaffolds could not be balanced safely | Safe with oscillating axle, tracked tires, or stabilizer system Safely lifts workers, while keeping ground stability |

| PRODUCTIVITY | Laborious Scaffolds have to be brought into the compound and set up | Convenient with up-and-over boom Can perform tasks from outside the compound |

| SPEED | Slow Requires set up, dismantling, climbing | Fast < 1 Minute to reach full height |

What Aerial Lift Users Should Be Aware Of

A good rule of thumb is to always treat power lines, wires, and other conductors as if they were energized, even if they are down or appear to be insulated. If you can’t avoid power lines completely, stay at least 3 meters away to avoid possible accidents. You should also avoid placing aerial lifts between power lines and other overhead hazards if possible.

Conclusion

When you assess the expense of purchasing the type of construction equipment used in the Philippines’ energy industry, renting is favorable due to the extremely high costs associated with owning the equipment, especially since it is often used for a short amount of time or a single task. Rely on Mayon Machinery to help you complete certain tasks, ensuring a more resilient and efficient power supply system throughout the Philippines.