Different work requires different tools. Pairing your compact loaders with a variety of attachments can help you improve safety and efficiency. In order to assist you in determining which attachments are best suited for landscaping tasks – planting trees, clearing land, installing underground irrigation systems, creating paths, placing landscape materials, or moving pallets, we are delighted to present the top 8 must-have attachments.

1. Bucket

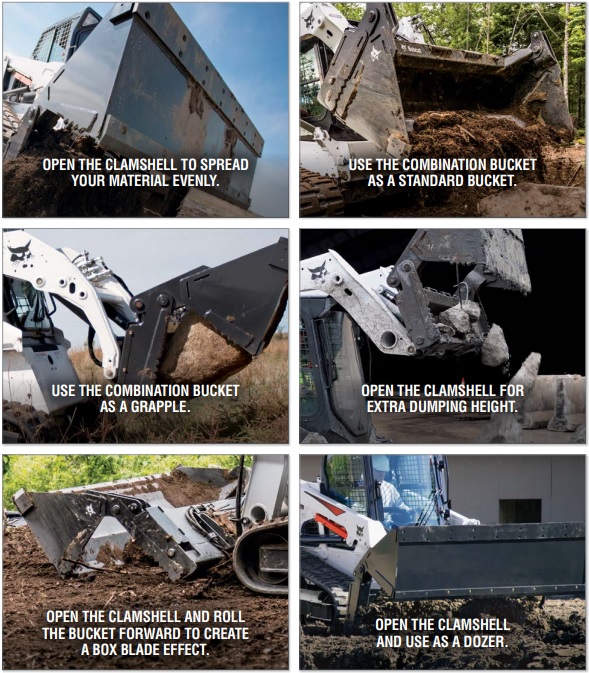

Buckets may not be the most glamorous or exciting tools, but definitely, they are some of the most versatile and useful ones you can have in your arsenal. Whether you have a skid steer loader or track loader, upgrading beyond the standard bucket opens up a world of possibilities from digging into and moving large piles of dirt or heavy landscaping rock to transporting larger materials like stone and concrete pavers. On job sites like building retaining walls or creating landscaping berms, buckets do significant work, and selecting the appropriate one is crucial to meet the demands of your applications. Our tips can help guide you in choosing the right bucket for your needs, which you can find by visiting this article.

2. Pallet Fork

The pallet fork is a commonly used attachment in the landscaping business that allows you to lift and transport bulky, bagged, or palletized materials with ease and speed. This powerful tool comes in standard and medium-duty options, both designed to offer excellent strength and durability. It features side steps that make getting in and out of the cab easy, and a standard, see-through spill guard that ensures excellent visibility. With this attachment, you can now easily plan to sod the backyard, lay pavers to create a garden path, create new garden beds, and haul in bags of potting soil or specialty mulch.

3. Auger

Planting small trees and shrubs throughout your property or installing a new fence or pergola can transform your property’s curb appeal – but can also require days of backbreaking work with a shovel. An auger attachment has the power to quickly, efficiently, and accurately dig holes for things like trees, shrubs, and fencing, deeper and faster – even in hard, rocky soil. So you spend less time and effort digging by hand, and more time enjoying the result of your handiwork. Choosing an auger that is too big for your machine will put unnecessary stress on the compact loader and keep it from running efficiently. It’s about balance involving machine weight, power, system pressure/flow rates, auger diameter, digging depth, and soil classification. Make sure to pick an auger drive to match the flow and pressure of the compact loader (standard or high flow) and that will handle the diameter of the auger that you would like to use. Keep in mind that the higher the flow rate, the faster the auger will rotate. Compare how much GPM your compact loader auxiliary hydraulics produce to the ratings of the auger attachment you are planning to purchase. If the compact loader produces 16 GPM you should choose among auger attachments rated at 10-20 GPM. When working with good digging conditions, such as sand, clay, and loam soils, choose an auger for its speed to increase productivity. Choose an auger with a higher volume of torque to break up harder materials such as compacted soil, asphalt, concrete, and frozen surfaces. The tougher the conditions, the larger the hole, and the deeper the hole the more you will prefer torque over speed. Speed would be the best choice if you are digging in plain dirt or sand to allow the auger to throw the material off the auger. The depth of a dig depends directly on the length of the auger bit. They are approximately 1.2m in overall length and available for round or hex drive augers. A hex drive shaft uses six sides to drive the auger into the ground, giving it more driving surface, which ultimately results in longer wear life, and is ideal for tough digging conditions such as compacted dirt, asphalt, concrete, and frozen surfaces. Adapters are available to convert a round auger drive to a hex bit and vice versa. Two basic types of auger drives are available – chain reduction drives and planetary drives. A planetary drive will usually offer more longevity than a chain drive. It generally has a lot less maintenance. If something breaks, it will be more costly to fix. A chain drive will typically have a lower cost than a planetary drive but is more susceptible to wear and tear from outside elements like rock, dirt, and sand.

4. Landscape Rake/ Auto Rake

Landscape rake, also referred to as auto rake, is an excellent attachment for grooming and finishing soil for seeding. They are ideal for a variety of projects ranging from turf and seeding to heavy-duty landscaping. Landscape rake can rake and collect surface debris while smoothing and leveling the soil over large areas. Once it is full, collected debris can be easily dumped at a chosen location. This attachment is also used for removing roots, rocks, and other debris that may be present in the topsoil before grading. The tines of the landscape rake can cut soil, allowing it to separate and aerate the soil, making it perfect for soil conditioning. In simple words, landscape rakes are the perfect tool for ensuring your soil is in ideal condition for your landscaping needs.

5. Trencher

Trenchers are a staple piece of equipment on landscaping job sites. From digging and moving dirt to cutting through rock, contractors know that the trenchers allow them to install utilities quickly and efficiently. Designed with the power and strength to dig in hard and rocky soil, teeth and chain options give you more versatility, thereby enabling the maximization of trenching capabilities for various soil conditions. Trenchers come in different sizes, with digging depths ranging from 609mm to 1524mm and trench widths spanning between 152mm and 305mm. The manual or hydraulic side shift feature is crucial as it allows users to dig close to buildings, fences, and other obstacles on the jobsite, thereby reducing the need for manual labor and improving efficiency. Single Standard chains, equipped with cupped teeth on every other section, are recommended for light to moderate digging in loose, damp, clay, and loamy soils. Double Standard chains, featuring roughly twice the number of teeth, are recommended for harder, drier soil. Half Rock & Frost chains are the go-to option for harder, frozen, and rocky digging conditions.

6. Grapple

Do you need to move heavy and hard-to-handle materials such as brush, logs, demolition debris, and landscaping stones? Take heart in knowing that grapple attachments have got you covered, with different configurations that are perfect for managing even your toughest landscaping work.

The Brush Root Grapple, for instance, is designed to deliver maximum chomping and ripping power, making it ideal for handling awkward materials such as logs, tree stumps, brush, rocks, roots, overgrowth, debris, loose hay, or straw without driving teeth into the ground; allows dirt to fall on-site.

You can also count on the Industrial Grapple which is excellent for moving heavier, hard-to-manage materials such as odd-shaped objects and scrap materials derived from broken-up concrete and rebar, landscape timbers, or lumber from old decking and docks. The two-arm design of the larger industrial grapple grabs hold of material in two places. As a result, you get maximum contact with material and strong biting force across irregular-shaped loads. With easy-to-use hydraulic controls, any operator can securely handle bulky or uneven loads.

There are specialized grapple attachments for rocks and long loads, known as Skeleton Rock Grapple and Log Grapple.

The Skeleton Rock Grapple is specifically designed to scrape with loader arms against boom stops. Its see-through design allows for excellent visibility, while the tines permit dirt to fall through. Additionally, the grapple offers complete protection of the hose routing, providing an added layer of safety.

The Log Grapple is an excellent attachment for handling logs, pipes, brushes, and other bulky materials. It features 2″ (508 mm) x 8″ (3032 mm) cylinders, and will close to a log or pipe as small as 6″ (1524 mm).

The versatile Rotating Grapple 180 Degrees attachment has the ability to rotate up to 180 degrees featuring spring-centered return, lateral lock, and in-line lock positions for handling material at different angles. Designed to lift and handle heavy, awkward-sized material such as logs, culverts, water pipes, telephone poles, and more with controlled precision. Load, unload, and transport material up to 1500 lbs (680kgs). The serrated cradle of the grapple steadies material in-line for straight-on loading or transport. The grapple tines open to a maximum of 39″ (990 mm) for grappling large objects and fold together as tight as 3″ (76 mm) in diameter for holding pipe, brush, or smaller material.

The single-cylinder Utility Fork Grapple attachment has optimal holding ability for hard-to-handle light materials such as manure, loose hay, straw, sod, silage, bedding, and other bulk materials. You can quickly and easily add more teeth, allowing you to handle smaller materials with improved efficiency within a few minutes.

A Grapple Bucket is typically used on hard flat surfaces. Materials are scraped into a hard bucket, producing a clean lift and sweep. The attachment securely collects debris materials, making removal a breeze anywhere you need to! Available in Standard, Medium, and Heavy-Duty models in widths ranging from 60” (1524 mm) to 88” (2235 mm), with independently operating grapple arms that can powerfully clamp onto uneven loads.

So, don’t let heavy materials weigh you down – let our grapple attachments inspire you to tackle even the most challenging landscaping work with ease.

7. Soil Conditioner & Roto Tiller

If you’re starting a new garden bed or need to thoroughly prepare the soil, a Roto Tiller is a good choice. This is an ideal attachment for breaking up clumps and mixing compost or other materials into existing soil. Its versatile functionality enables you to operate it in a forward or reverse motion, making it ideal for optimal seedbed preparation and other landscape functions.

Soil Conditioner is gentler and won’t disrupt the soil as extensively as Roto Tiller, ideal for maintaining existing landscapes and improving soil texture. It prepares soil while leveling and filling in fewer passes. Its carbide-tipped teeth easily rip through clumps while penetrating the ground. It has an easy-to-maintain direct-drive hydraulic motor, and no chains or sprockets to worry about.

8. Tree Spade & Transplanter

The best attachment for planting trees is the Tree Spade. Move and place trees, shrubbery, and boulders and dig holes for new trees all with the same attachment. There are three types of blade configurations on tree spades, each suited to a type of soil and each providing a different type of root ball size from 36” (914 mm) to 48” (1219 mm). Landscapers using the tree spade attachment should remember the 10-1 ratio. Multiplying the diameter of the tree trunk by 10 will give the size of the tree spade to use. For instance, a tree with a trunk diameter of 3 inches requires a 30-inch tree spade.

Tree Transplanter allows you to take advantage of the power of your compact loader to plant, transplant, and remove mature trees with up to 50” (1270 mm) diameter root balls. This heavy-duty attachment comes standard with 3, 4, or 6 semi-truncated 1/4” high alloy steel blades and additional valve port for operating rear stabilizers.

An attachment works best when it is used properly, and that’s a key aspect of Mayon Machinery‘s service. Contact us today to get more out of your compact loaders through our top-quality landscaping attachments. No matter what your landscaping needs are, whether it’s a small-scale project or a complete overhaul of your outdoor space, we are ready to assist you in getting the job done safely and efficiently.