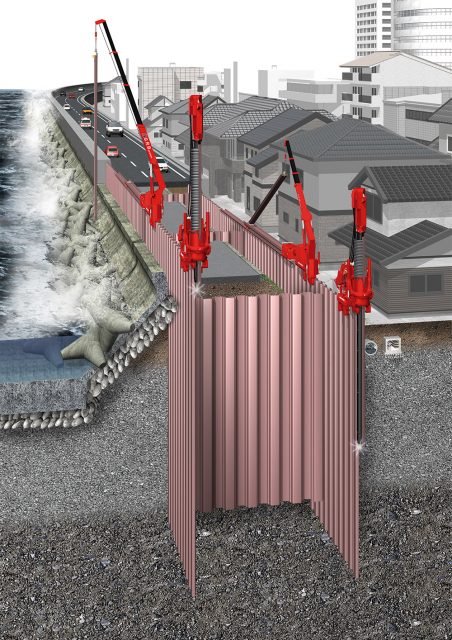

The Philippines is an island country consisting of some 7,400+ islands and islets and have a coastline of approximately around 37,000 km. However, flood risks due to natural coastal hazards (surges, typhoon waves, and tsunamis) threaten the loss of life and damage to the properties of its residents. To minimize devastating consequences, a disaster prevention levee is an important coastal protection solution by Giken’s Innovative Technologies. Implant Levee that is securely integrated with the Earth is highly resistant to ground displacement caused by the motion dynamic loss of external force such as earthquakes, and tsunamis, thus, serving as a ”resilient” disaster-prevention infrastructure.

What’s Implant Levee?

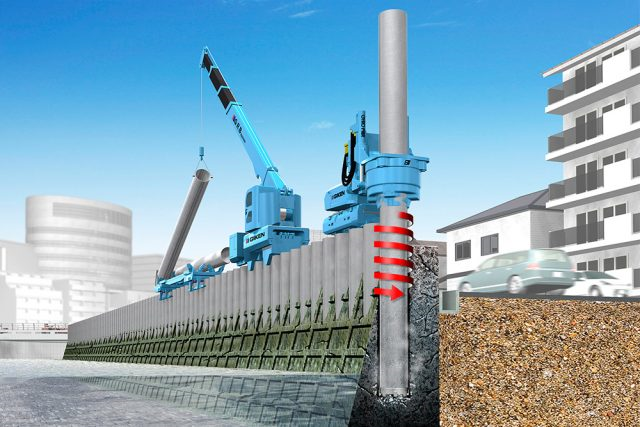

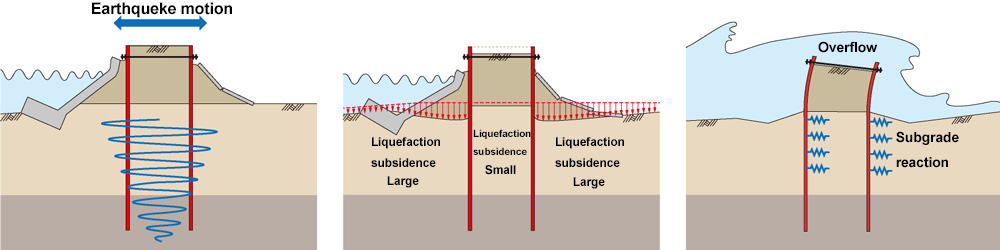

An implant levee is solid and strong against complex disasters such as earthquakes, tsunamis, and land subsidence. For earthquake protection, an implant-structured pile continuous wall has a secure embedded depth that will not allow any large deformation. Also, as the side floating of liquefied soil is restrained, settlement of the levee body is restrained. Furthermore, by embedding the pile toe to the non-liquefied layer, subsidence of the pile itself will not occur, and the levee height may be maintained. With tsunami, even if the slope face collapses due to overflow, the pile continuous wall with the implant structure will keep its form, and thus maintain its levee function. After an earthquake, tsunami, or other disasters an implant levee may be used as an emergency transit route or drainage work base for fire engines by erecting a coverage plate using the remaining pile heads. This way, it becomes useful in the early restoration of disaster sites.

Coastal Levee Protection Methods

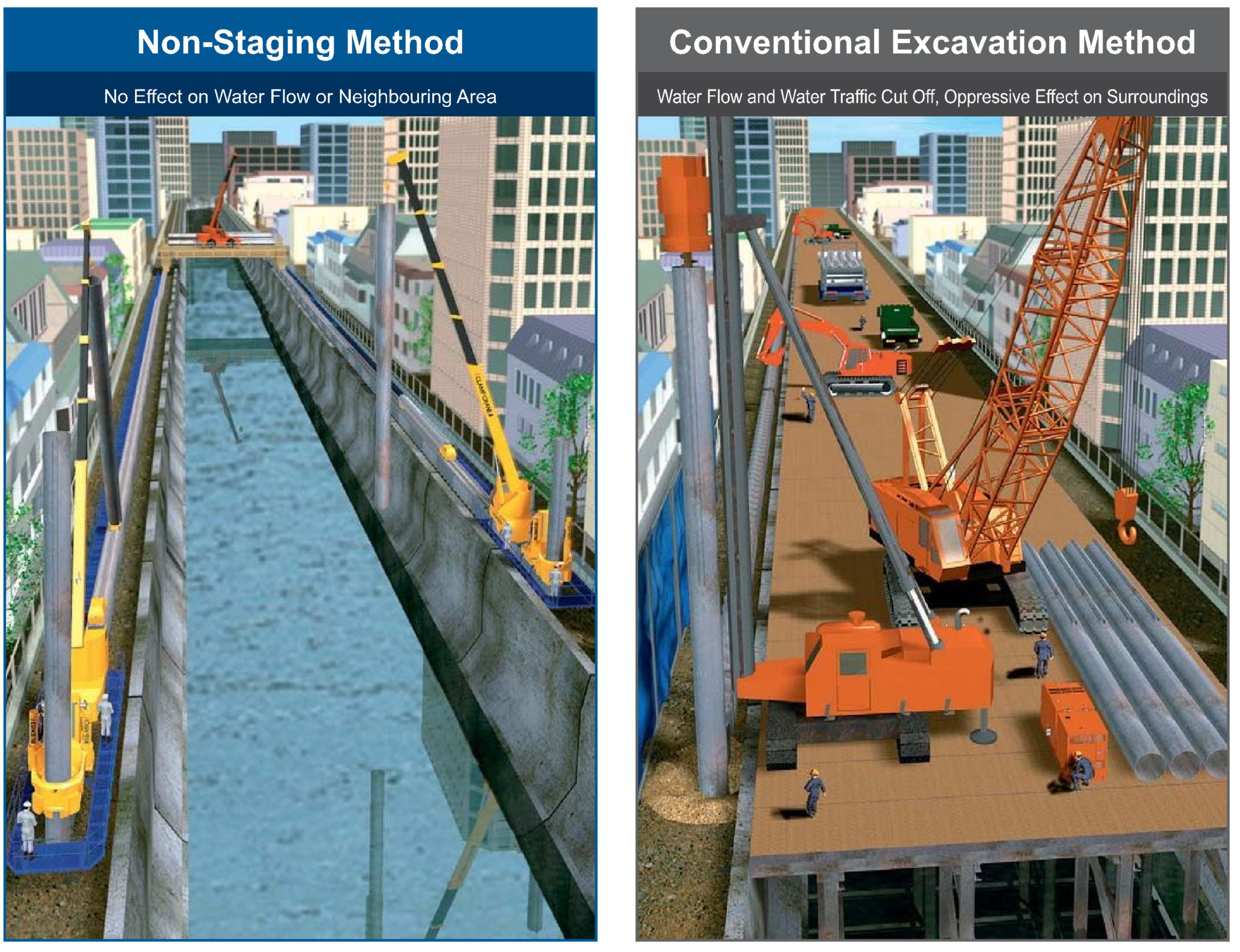

Two methods presented here are commonly applied in coastal levee protection in many countries, including Japan:

|

|

| Twin Sheet Pile Walls | Tubular Pile Wall |

| Steel sheet piles are installed into the embankment to a depth determined for proper stability and/or cut-off of flow. Also, liquefaction of the levee can be prevented by enclosing it with twin sheet pile walls. Thus, the levee can withstand large external loading and the levee crest can remain in place, even in catastrophic events. |

Steel tubular pile wall is a vertical barrier and can be installed in locations where space is scarce, such as urban environments or where the construction of a wide levee is not feasible. The piles are installed into the embankment to a depth determined for proper stability to withstand large dynamic and hydraulic loading. |

|

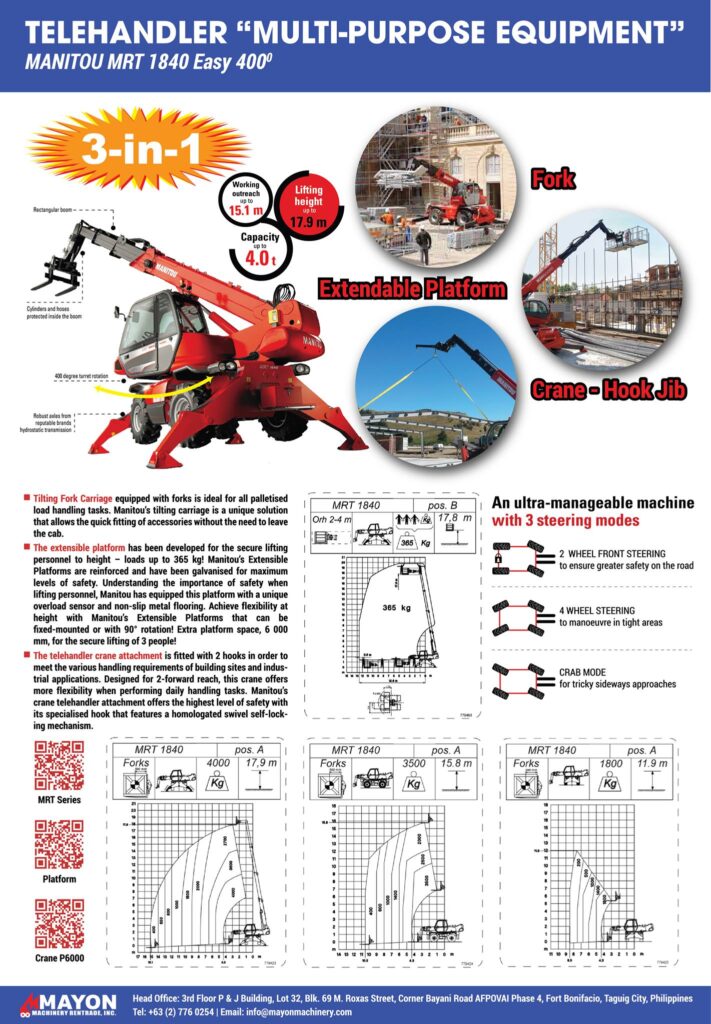

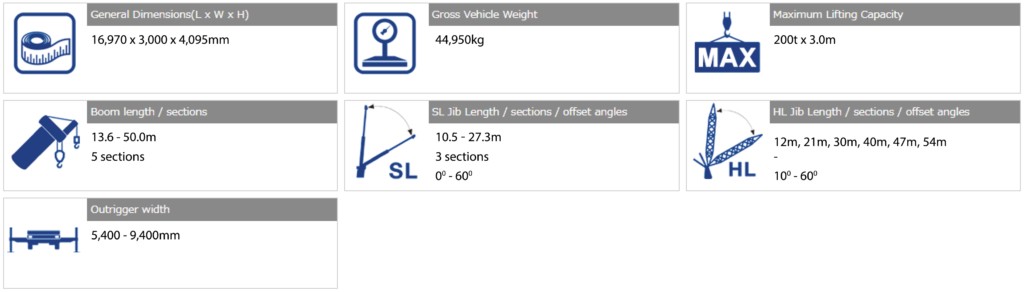

Giken Reaction Base (GRB) System |

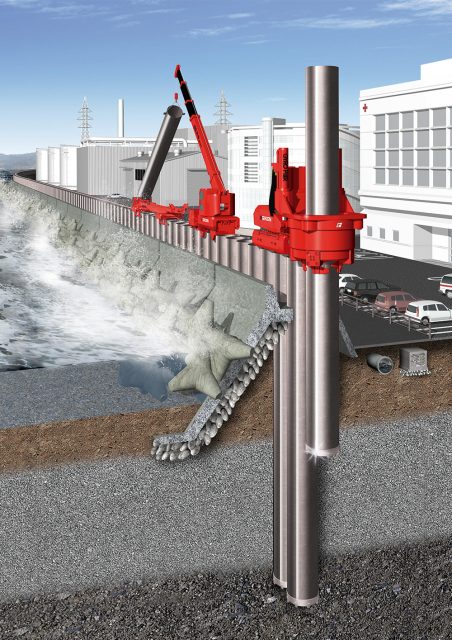

Gyropress Method |

|

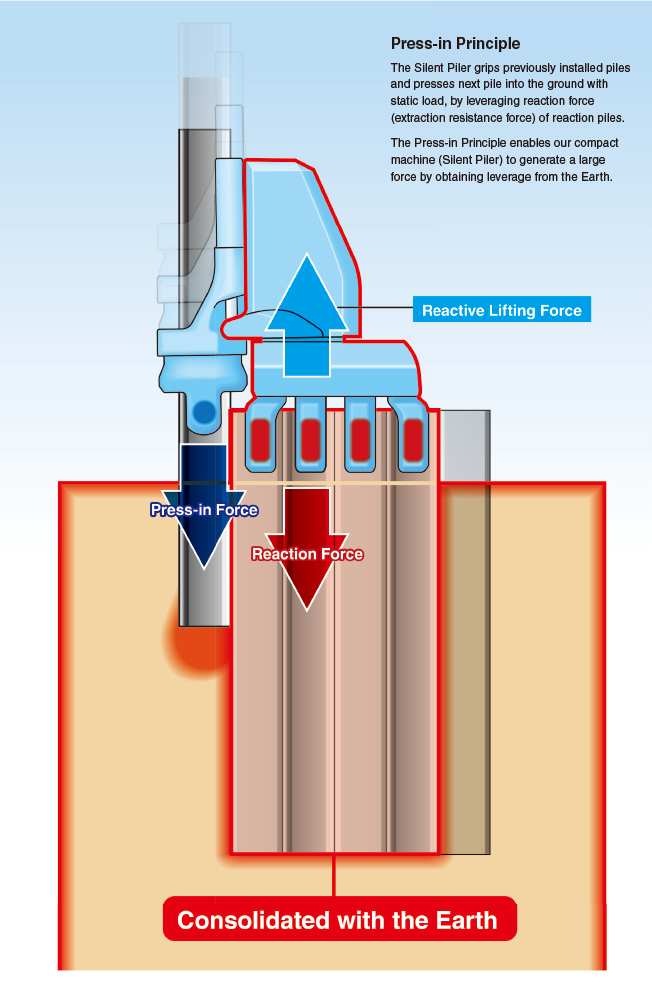

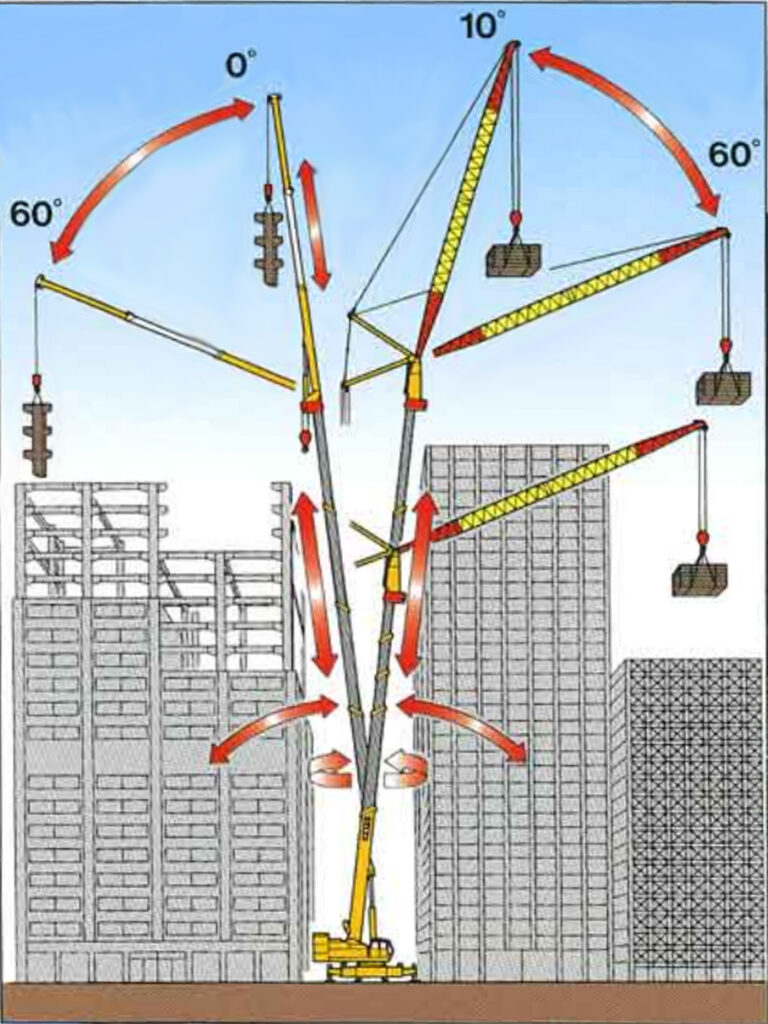

The press-in machine utilizes reaction force from previously installed piles and performs piling work on top of the piles. With further development based on the principle of “reaction-based mechanism”, “the GRB System” was developed as a press-in system that performs all piling procedures such as; pile transportation, pile pitching, and press-in work, on top of installed piles. The GRB System consists of a Silent Piler in the front, a Power Unit as a power source, a Clamp Crane to pitch piles, and a Pile Runner to convey piles from the storage site. |

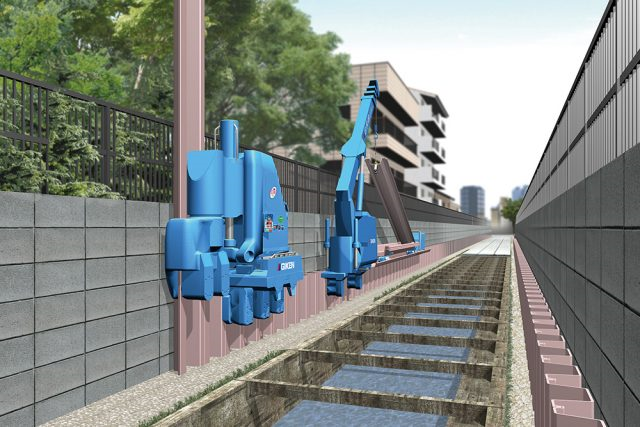

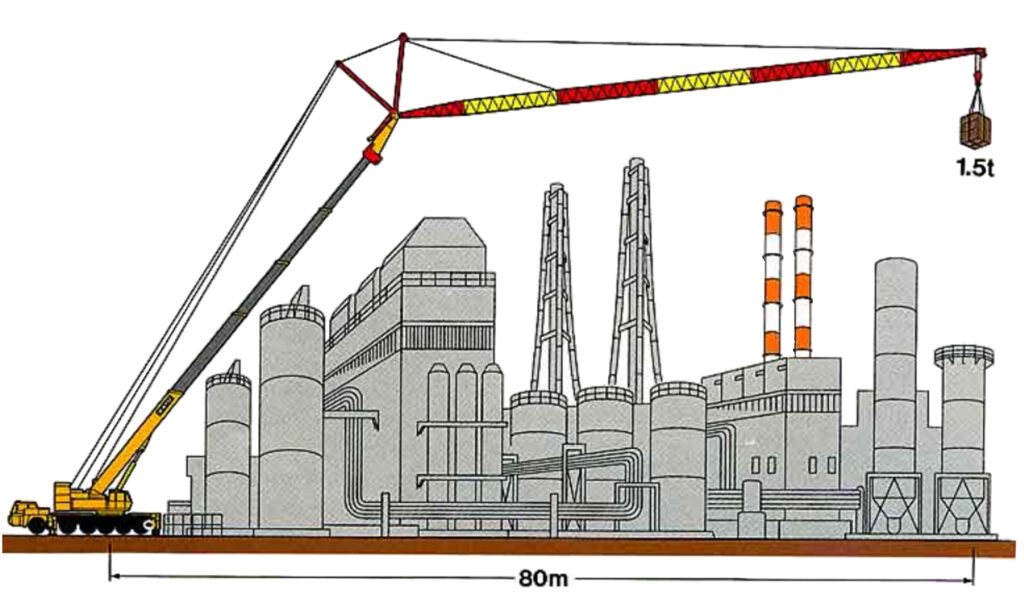

Gyropress Method installs tubular piles with cutting bits attached on pile toe by the rotary jack-in system and travels on top of piles that are completely installed (completed piles). Gyropress Method allows the installation of tubular piles without prior removal of existing structures and/or obstacles. |

Advantages of Implant Levee

- Flood, Storm Surge, and Tsunami Protection

Functions of the levee can be maintained by increasing its stability.

- Liquefaction Protection

Functions of the levee can be maintained by the ground enclosure effect.

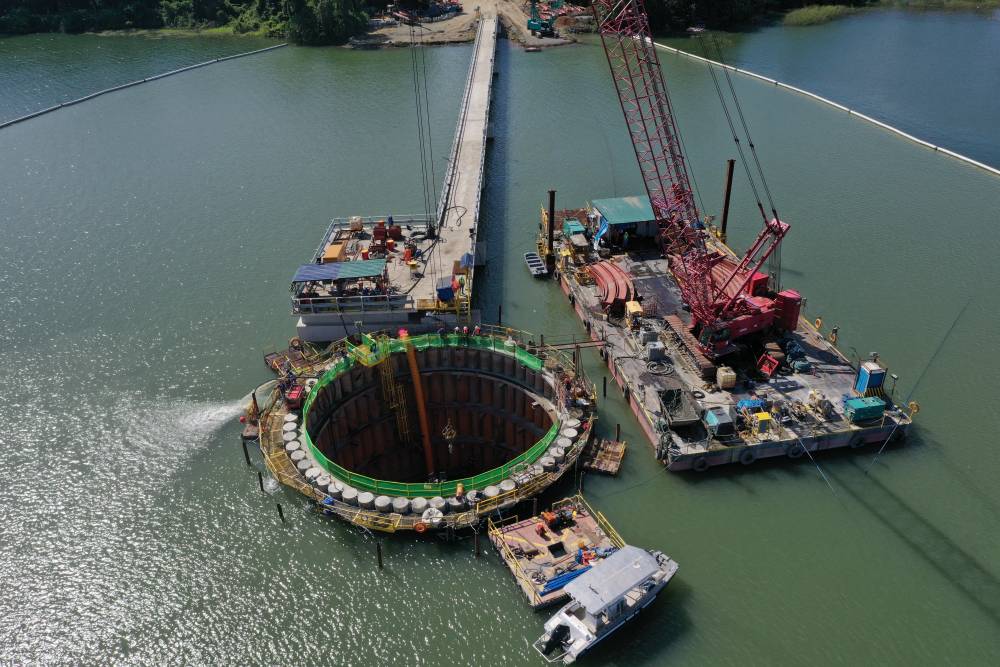

Application

- Coastal Protection for the Coastline of the Philippines.

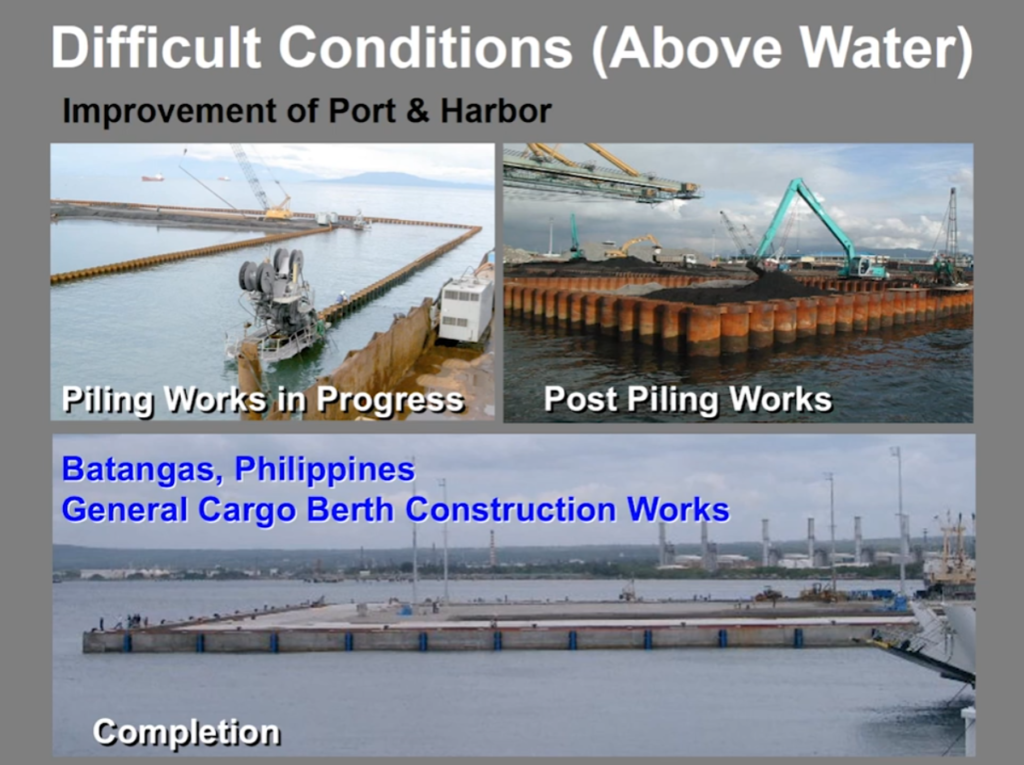

- Improvement of Port & Harbor.