Description

| Working height, max. | 50,00 m |

| Side reach, max. | 17,10 m (200 kg) / 20,00 m (80 kg) |

| Basket capacity, max. | 200 kg |

| Length with / without basket | 9,35 m / 8,45 m |

| Transport height x width, min. | 1,98 m x 1,58 m |

| Total weight | 13500 kg |

| Tracks, adjustable | Hydraulical (Standard) |

| Stabilisation system | Automatic, multi-position |

| Power source – standard | 400 V electric motor + Diesel |

| Power source – optional | 400 V electric motor + battery |

|

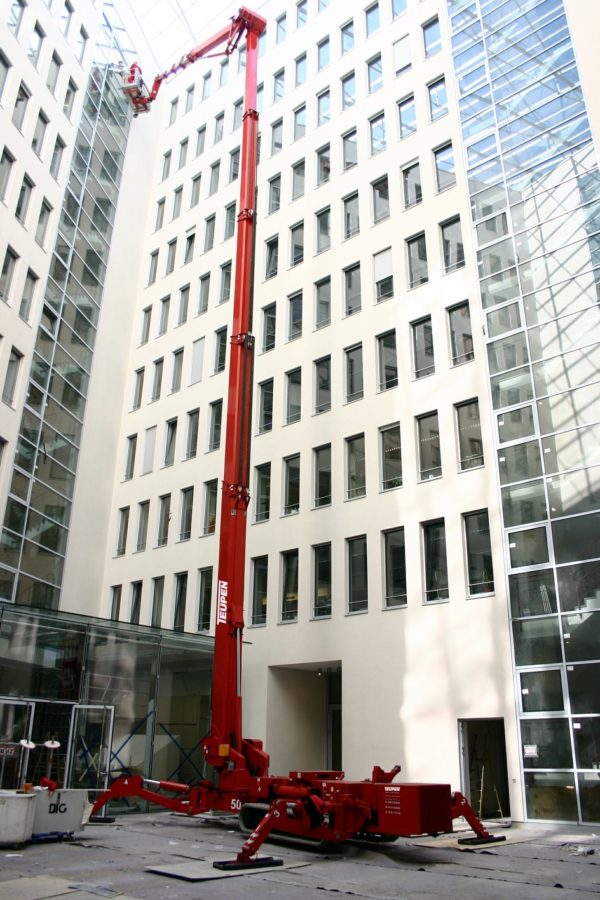

Superior to the last detailThe LEO50GT is the world´s most popular model in the large tracked aerial segment. It scores with the right balance between compactness, flexibility and performance. 50 metres working height and great outreach make it an efficient and quick solution in many applications such as facility management, high rise construction or the maintenance and service of utility networks. |

|

The TEUPEN track driveThe track drive with non-marking rubber tracks provides easy, precise maneuvering and protects sensitive flooring. In the standard configuration the LEO50GT is equipped with a hydraulically height- and width adjustable track drive at a touch of a button: The narrow setting decreases the width of the machine, in wide it increases ground clearance and stability. Also levelled driving alongside slopes is possible. The powerful TEUPEN track drive allows to master gradients and even stairs easily. |

|

High-performance stabiliser systemSafe positioning even with little space: The multi-position stabiliser system permits to automatically set up the machine in confined areas and on slopes. It offers two different setup positions: Both sides wide, one side wide and one side narrow. In terrain or over obstacles the stabilisers overcome a height difference of up to 1,00 m. |

|

Rotatable platformThe rotatable platform adds extra versatility to the lift operation. The LEO50GT features a 180° rotation for true extra flexibility and the most precise platform positioning possible. |

|

Intuitive control systemWith the radio remote control the LEO50GT is controlled from one spot – either from the platform or walking alongside the machine for the best overview while maneuvering. The radio remote control with clearly arranged color coded functions and only four joysticks for the entire lift operation supports intuitive and safe handling even for inexperienced users. |

|

Dual power sourceThe LEO50GT is equipped with a powerful Kubota Diesel engine for outdoor applications and a 400 V electric motor for a silent and zero-emission work inside of buildings. Optionally, the Diesel engine can be replaced by an 80 V battery drive. |